Email : zhou@sinobiochemistry.com Phone : +86-13941198570

Views: 0 Author: Site Editor Publish Time: 2025-12-15 Origin: Site

Water safety is critical for health and the environment. Have you ever wondered how we keep our water systems clean? Biocides for water treatment play a vital role in this process.

In this article, we will explore what biocides are and their importance in maintaining water quality. You'll learn about different types of biocides and how they effectively combat microbial growth.

Biocides are chemical substances designed to control harmful organisms. They play a crucial role in various applications, especially in water treatment. These agents work by disrupting the cellular processes of microorganisms, effectively reducing their numbers and preventing growth.

In water systems, biocides are essential for maintaining hygiene and safety. They target bacteria, fungi, and algae, which can cause contamination. By controlling these microorganisms, biocides help ensure that water remains safe for human use and aquatic life.

Type of Biocide | Common Uses | Target Organisms |

Oxidizing Biocides | Disinfection in treatment plants | Bacteria, viruses, algae |

Non-Oxidizing Biocides | Industrial cooling systems | Biofilms, fungi, bacteria |

Biocides play a vital role in preventing contamination in various water systems. Their primary function is to maintain water quality by eliminating harmful microorganisms. This is especially important in systems such as cooling towers, boilers, and wastewater treatment facilities.

In cooling towers, for instance, biocides prevent biofouling, which can lead to reduced efficiency and increased maintenance costs. Similarly, in boilers, controlling microbial growth helps prevent corrosion and extends equipment lifespan.

Here are some examples of water systems where biocides are critical:

● Cooling Towers: They require constant monitoring and biocide application to prevent algae and bacteria growth.

● Boilers: Biocides help maintain water quality, ensuring efficient heat transfer and preventing scale buildup.

● Wastewater Treatment: Biocides are essential for controlling pathogens and ensuring treated water is safe for discharge.

By understanding the importance of biocides in these systems, we can appreciate their role in safeguarding public health and maintaining environmental integrity.

Oxidizing biocides are powerful agents that kill microorganisms by disrupting their cellular functions. They work through a chemical reaction that introduces oxygen into the cells, leading to cell death. This category includes several common types, each with unique characteristics.

Halogen-based compounds, such as chlorine and bromine derivatives, are widely used in water treatment. These compounds are effective against a broad range of microbes, including bacteria, viruses, and algae.

Compound | Usage | Target Organisms |

Chlorine | Disinfection in pools | Bacteria, viruses |

Bromine | Cooling towers | Algae, bacteria |

However, their effectiveness can be influenced by pH levels. For instance, chlorine's efficacy decreases in high pH conditions, which can lead to corrosion in some systems. Therefore, careful monitoring is necessary to optimize performance and minimize damage.

Another important category is peroxygen compounds, which include hydrogen peroxide and peracetic acid (PAA). These agents are known for their strong oxidizing power, making them highly effective at killing microorganisms.

● Hydrogen Peroxide: It decomposes into water and oxygen, leaving no harmful residues.

● Peracetic Acid: This compound is particularly useful in food processing and water treatment due to its high efficacy against a wide range of pathogens.

The advantages of using peroxygen compounds include their ability to break down without leaving halogenated byproducts, which can be harmful to the environment. This makes them a preferred choice in many applications.

Non-oxidizing biocides function differently from their oxidizing counterparts. They kill microorganisms through various mechanisms, such as disrupting metabolic pathways or damaging cell membranes. This category includes several key types.

Quaternary ammonium compounds, often referred to as quats, are effective surface-active agents. They work by penetrating and dispersing biofilms, particularly in systems that experience lower fouling.

● Effectiveness: Quats are known for their ability to maintain cleanliness and prevent microbial growth in surfaces and water systems.

● Applications: Commonly used in hospitals and food processing facilities, quats help ensure hygiene standards are met.

Isothiazolinones, including CMIT and MIT blends, are another class of non-oxidizing biocides. They offer broad-spectrum efficacy against bacteria and fungi, making them suitable for various applications.

● Stability: These compounds exhibit good stability in different water conditions, which is crucial for consistent performance.

● Formulations: Their effectiveness varies depending on the formulation, so understanding specific blends is important for application.

Glutaraldehyde is known for its rapid action and broad efficacy, particularly against sulfate-reducing bacteria (SRB). This biocide is often used in industrial applications where quick microbial control is essential.

● Application: It is effective in treating cooling water systems and wastewater.

● Stability: Glutaraldehyde remains stable in various conditions, ensuring reliable performance.

Dithiocarbamates and thiones are agents frequently used for their strong fungicidal and algaecidal properties. These compounds have garnered interest due to their environmental persistence and regulatory status.

● Environmental Considerations: Understanding their impact on the environment is vital, especially in sensitive ecosystems.

● Regulatory Status: Compliance with regulations ensures safe use in various applications.

These diverse types of biocides for water treatment play crucial roles in maintaining water quality and safety. By understanding their mechanisms and applications, we can make informed choices for effective water management.

When selecting biocides for water treatment, efficacy is crucial. It’s essential to choose biocides based on their effectiveness against specific microorganisms. Different biocides target various pathogens, so understanding the specific needs of your system is key.

For instance, oxidizing biocides like chlorine are excellent for quick disinfection, while non-oxidizing biocides, such as isothiazolinones, provide prolonged control against biofilms. Here’s a quick comparison:

Biocide Type | Speed of Action | Duration of Effect | Microorganisms Targeted |

Oxidizing Biocides | Fast | Short-term | Bacteria, viruses, algae |

Non-Oxidizing Biocides | Moderate | Long-term | Fungi, biofilms, bacteria |

Chemical compatibility is another vital consideration. When using biocides, it’s important to assess how they interact with system materials, such as metals and seals. Some biocides can cause corrosion or degradation, leading to system failures and costly repairs.

For example, chlorine-based compounds can be corrosive to certain metals. Therefore, selecting biocides that are compatible with your system materials is essential for long-term operation. Regular inspections and maintenance can help identify potential issues early.

Understanding the proper dosage and application of biocides is critical for effective water treatment. Each biocide has specific concentration ranges and required contact times to achieve optimal results.

● Typical Concentration Ranges: For example, chlorine might be effective at 1-5 mg/L, while quaternary ammonium compounds may require 100-200 mg/L.

● Contact Times: The required contact time can vary from a few minutes to several hours, depending on the biocide and target microorganisms.

Here are some best practices for dosing:

1. Regular Monitoring: Frequent testing of biocide levels ensures they remain within effective ranges.

2. Adjusting Based on Conditions: Factors like temperature and pH can influence biocide effectiveness, so adjustments may be necessary.

3. Training Staff: Ensuring that personnel understand proper dosing techniques can enhance overall system performance.

Choosing environmentally friendly biocides is increasingly important. Many industries are looking for solutions that minimize environmental impact. Biodegradability is a key factor here; biocides that break down quickly reduce the risk of harmful by-products accumulating in the environment.

● Biodegradable Options: Compounds like peracetic acid are preferred for their rapid breakdown into harmless substances.

● Harmful By-Products: Some biocides can produce toxic by-products, which pose risks to aquatic life. Understanding these profiles helps in making informed decisions.

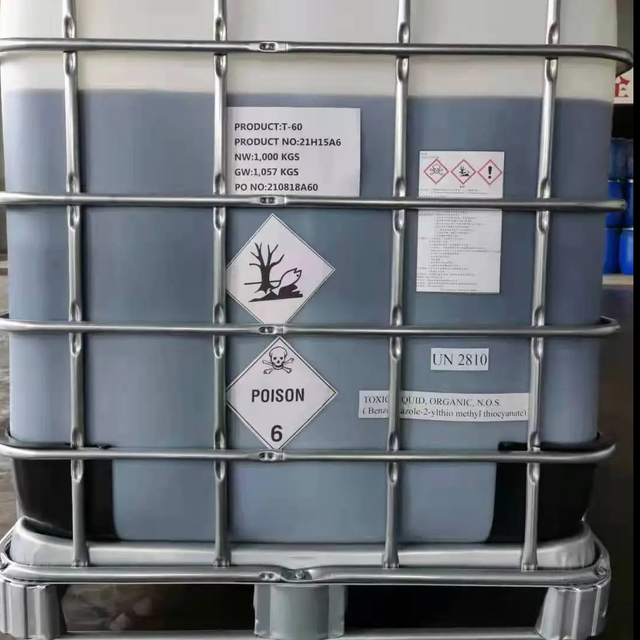

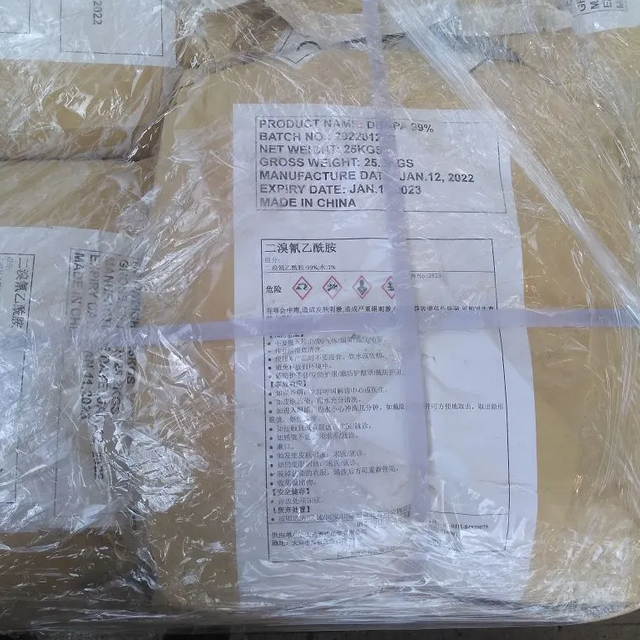

Safety is paramount when handling biocides. Proper precautions must be taken to protect workers and the environment. Here are some essential safety measures:

● Personal Protective Equipment (PPE): Always wear appropriate PPE, such as gloves, goggles, and masks, to prevent exposure.

● Storage Guidelines: Biocides should be stored in a cool, dry place away from incompatible substances. Proper labeling and safety data sheets (SDS) should be readily available.

● Emergency Procedures: Establish clear procedures for spills or accidental exposure, including first aid measures and emergency contacts.

By considering these key factors, you can effectively use biocides for water treatment, ensuring safety, efficiency, and environmental responsibility.

Sodium Dichloroisocyanurate, commonly known as SDIC, is a powerful chlorinated compound used extensively in water treatment. It features a high active chlorine content, typically around 56%, making it effective for disinfection purposes. SDIC is particularly advantageous in both municipal and industrial settings due to its versatility.

● Applications: It is widely used in drinking water treatment, swimming pools, and industrial water systems.

● Stability: One of its strengths is its stability across a range of pH levels, ensuring consistent performance. This makes it suitable for various water conditions, maintaining its efficacy even in challenging environments.

Specification | Value |

Active Chlorine | 56% |

Form | Granular, stable at various pH |

Main Uses | Drinking water, pools, industrial |

TTPC biocide is specifically formulated to combat biofouling in water systems. Its targeted action is effective against various microorganisms that form biofilms, which can disrupt system efficiency.

● Application Scenarios: It finds use in industrial cooling towers, wastewater treatment plants, and other systems where biofouling is a concern.

● Long-lasting Control: One of the key benefits of TTPC is its ability to provide long-lasting microbial control, reducing the frequency of applications required and enhancing system reliability.

Methylisothiazolinone, or MIT, is a widely recognized biocide known for its broad-spectrum effectiveness. It is particularly effective in controlling bacteria and fungi in various water treatment applications.

● Specifications: Typically available as a 50% aqueous solution, MIT is favored for its reliable performance.

● Customer Feedback: Users often praise its consistency and effectiveness, with many noting that batch-controlled quality ensures dependable results. This reliability is crucial in maintaining water quality standards.

Bronopol is another effective biocide, especially noted for its efficacy against gram-negative bacteria. This property makes it particularly useful in cooling water systems and wastewater treatment.

● Use Cases: It is commonly employed in applications where bacterial contamination is a concern, helping to maintain system integrity.

● Quality Assurance: Bronopol is classified as an industrial-grade product, typically boasting a minimum purity of 99%. This high level of purity ensures effective performance in demanding environments.

Biocide | Target Organism | Typical Use |

Bronopol | Gram-negative bacteria | Cooling systems, wastewater |

Trichloroisocyanuric Acid, or TCCA, is a well-known chlorinated compound used primarily for disinfection. It offers several advantages over traditional bleaching agents, making it a popular choice in water treatment.

● Advantages: TCCA provides longer-lasting chlorine stability, which is beneficial for continuous disinfection applications. This stability is particularly valuable in situations where consistent water quality is essential.

● Applications: It is commonly used in drinking water treatment and swimming pool sanitation, effectively eliminating pathogens and controlling algae growth.

Chlorhexidine Diacetate Salt is renowned for its safety and broad-spectrum antimicrobial activity. It is particularly useful in food and beverage water treatment, ensuring that water used in these industries meets strict safety standards.

● Applications: Beyond food processing, it is also applied in aquaculture, where it helps protect aquatic organisms from harmful pathogens.

● Safety Profile: This biocide is favored for its low toxicity and effectiveness, making it a reliable choice for sensitive applications.

In summary, these biocides for water treatment each offer unique benefits and applications. Understanding their specific characteristics helps in selecting the right biocide for various water treatment needs.

Dalian Sinobio Chemistry Co., Ltd. is a leading manufacturer in the biocide industry, specializing in high-quality chemical solutions for water treatment. Established with a vision to provide effective and safe biocides, the company has built a solid reputation over the years. Their commitment to quality and innovation sets them apart in a competitive marketplace.

● Commitment to Quality: Sinobio adheres to strict quality control measures, ensuring that every product meets international standards.

● Innovation Focus: The company invests heavily in research and development, continuously improving its product offerings to meet evolving market needs.

Sinobio's biocides come with several core advantages that make them a preferred choice for many industries. Their extensive industry experience and technological advancements ensure reliable performance.

Advantage | Description |

Industry Experience | Over 20 years in the biocide market, ensuring expertise. |

Technological Advancements | State-of-the-art production facilities enhance quality. |

Customer Satisfaction | High repeat business due to reliable product performance. |

Customers appreciate Sinobio's dedication to delivering effective solutions. The advanced production technology and automatic control systems guarantee consistency and quality in every batch.

One of the standout features of Dalian Sinobio Chemistry is its robust technical support system. The company provides comprehensive assistance to ensure optimal biocide performance in various applications.

● Support Overview: They offer expert guidance on product selection and application, helping customers achieve the best results.

● Customizable Solutions: Sinobio understands that each water treatment scenario is unique. They provide tailored solutions to meet specific customer needs, ensuring maximum effectiveness.

In addition, Sinobio offers 24/7 technical assistance, allowing customers to reach out for help with dosage adjustments or troubleshooting applications at any time. This commitment to customer service enhances user experience and satisfaction.

By choosing biocides from Dalian Sinobio Chemistry Co., Ltd., customers benefit from a combination of quality products, expert support, and innovative solutions designed to meet diverse water treatment needs.

Biocides play a crucial role in water treatment, ensuring safety and quality. They help control harmful microorganisms in various systems.

Consider effective biocide solutions to maintain optimal water quality. We encourage you to explore different biocide options. Consulting with experts can provide tailored solutions for your specific needs.

A: Effective biocides include sodium dichloroisocyanurate (SDIC), methylisothiazolinone (MIT), and trichloroisocyanuric acid (TCCA).

A: Consider the specific microorganisms present, system materials, and environmental conditions to select the appropriate biocide.

A: Yes, options like peracetic acid and certain isothiazolinones are known for their lower environmental impact.

A: Use personal protective equipment (PPE), follow storage guidelines, and ensure proper labeling and training.

A: Application frequency depends on the biocide type and water conditions; regular monitoring is essential for optimal results.