Email : zhou@sinobiochemistry.com Phone : +86-13941198570

| Availability: | |

|---|---|

| Quantity: | |

DBDPE 80%

Sinobio

29039990

Decabromodiphenyl Ethane (DBDPE) stands out as an innovative additive-type flame retardant, boasting a comprehensive range of performance advantages that make it widely applicable across multiple industrial fields. Unlike traditional flame retardant options, it features a broad-spectrum flame suppression effect, capable of effectively inhibiting the combustion process of various polymeric materials—such as polyethylene, polypropylene, and ABS resins—thereby reducing fire risks in end products like electronic enclosures, wire and cable insulation, and building materials.

In terms of core performance, this flame retardant excels in two key aspects: superior thermal stability and high bromine content. Its excellent thermal stability ensures that it remains chemically stable even when exposed to high-temperature processing conditions (typically with a decomposition temperature exceeding 300°C), avoiding thermal decomposition that could affect the mechanical properties of the base material or generate harmful by-products. Meanwhile, its high bromine content (usually above 82%) enables it to achieve optimal flame retardant efficiency with a relatively low addition amount, minimizing the impact on the physical and mechanical properties of the processed materials, such as tensile strength and impact resistance.

Beyond its core flame retardant capabilities, DBDPE also possesses notable auxiliary advantages. It exhibits strong UV resistance, allowing materials treated with it to maintain stable flame retardant performance and physical appearance even in long-term outdoor or UV-exposed environments, without experiencing issues like performance degradation or color fading. Additionally, it meets modern environmental protection and safety requirements with its low toxicity characteristic: it does not contain substances that are harmful to the ozone layer (such as polychlorinated biphenyls) and has minimal acute and chronic toxicity to humans and the ecological environment, complying with international environmental standards such as RoHS and REACH. These advantages collectively make it a preferred flame retardant choice in industries pursuing high performance, environmental friendliness, and safety.

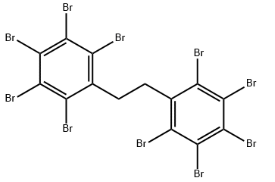

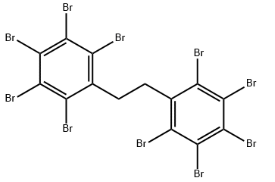

| Chemical Name | Decabromodiphenyl Ethane | CAS No. | 84852-53-9 |

| MF | C14H4Br10 | MW: | 971.22 |

| EINECS | 284-366-9 | Structural Formula |  |

| Melting point | 345 °C | Boiling Point | 676.2±50.0 °C(Predicted) |

| Density | 2.816±0.06 g/cm3 | Appearance | Solid |

| Color | Off-White to Pale Beige | Solubility | Dioxane (Very Slightly, Heated) |

DBDPE (decabromodiphenyl ether), as a new, highly effective, and environmentally friendly brominated flame retardant, offers numerous significant advantages, specifically in the following areas:

*Highly Efficient Flame Retardancy: DBDPE's extremely high bromine content enables it to rapidly decompose during combustion, producing halogen free radicals. These halogens effectively capture reactive oxygen radicals in the combustion reaction, interrupting the combustion chain and achieving excellent flame retardancy.

*Long-Lasting Stability: DBDPE exhibits excellent thermal stability, maintaining stable flame retardancy even in high-temperature environments, making it suitable for prolonged use.

*Low Persistence: Compared to traditional polybrominated diphenyl ether flame retardants, DBDPE exhibits lower environmental persistence, meaning it does not accumulate in ecosystems over long periods of time, reducing potential harm to wildlife.

*Low Volatility: DBDPE's low volatility reduces potential impacts on the environment and human health during use.

*Low Waste: DBDPE generates less waste during its production process, further reducing environmental impact.

*Multiple Applications: DBDPE is widely used in a variety of applications, including plastics, rubber, resins, coatings, and textiles. As a highly effective additive flame retardant, it can significantly enhance the flame retardancy of these materials.

*Strong Compatibility: DBDPE is highly compatible with other materials without affecting their physical and chemical properties, making it highly versatile in a variety of industrial applications.

*Improved Material Properties: In practical applications, using DBDPE as a flame retardant not only does not compromise the flame retardancy of a material, but can actually improve physical properties such as impact strength, elongation at break, and dimensional stability.

*Enhanced Product Value: By adding DBDPE, manufacturers can produce products that combine excellent flame retardancy with good physical properties, thereby enhancing their market competitiveness.

| Melting point | 345°C |

| Boiling point | 676.2±50.0 °C(Predicted) |

| Density | 2.816±0.06 g/cm3(Predicted) |

| Storage temp. | Sealed in dry,Room Temperature |

| Solubility | Dioxan (Very Slightly, Heated) |

| Form | Solid |

| Color | Off-White to Pale Beige |

Packing: 25kg plastic woven bag, 1*20FCL=20MT with pallet. Also provide 500kg bag and 1,000kg ton bag.

Transport: Non-Hazardous chemicals

Recommended shelf life: 2 years

Decabromodiphenyl Ethane (DBDPE) stands out as an innovative additive-type flame retardant, boasting a comprehensive range of performance advantages that make it widely applicable across multiple industrial fields. Unlike traditional flame retardant options, it features a broad-spectrum flame suppression effect, capable of effectively inhibiting the combustion process of various polymeric materials—such as polyethylene, polypropylene, and ABS resins—thereby reducing fire risks in end products like electronic enclosures, wire and cable insulation, and building materials.

In terms of core performance, this flame retardant excels in two key aspects: superior thermal stability and high bromine content. Its excellent thermal stability ensures that it remains chemically stable even when exposed to high-temperature processing conditions (typically with a decomposition temperature exceeding 300°C), avoiding thermal decomposition that could affect the mechanical properties of the base material or generate harmful by-products. Meanwhile, its high bromine content (usually above 82%) enables it to achieve optimal flame retardant efficiency with a relatively low addition amount, minimizing the impact on the physical and mechanical properties of the processed materials, such as tensile strength and impact resistance.

Beyond its core flame retardant capabilities, DBDPE also possesses notable auxiliary advantages. It exhibits strong UV resistance, allowing materials treated with it to maintain stable flame retardant performance and physical appearance even in long-term outdoor or UV-exposed environments, without experiencing issues like performance degradation or color fading. Additionally, it meets modern environmental protection and safety requirements with its low toxicity characteristic: it does not contain substances that are harmful to the ozone layer (such as polychlorinated biphenyls) and has minimal acute and chronic toxicity to humans and the ecological environment, complying with international environmental standards such as RoHS and REACH. These advantages collectively make it a preferred flame retardant choice in industries pursuing high performance, environmental friendliness, and safety.

| Chemical Name | Decabromodiphenyl Ethane | CAS No. | 84852-53-9 |

| MF | C14H4Br10 | MW: | 971.22 |

| EINECS | 284-366-9 | Structural Formula |  |

| Melting point | 345 °C | Boiling Point | 676.2±50.0 °C(Predicted) |

| Density | 2.816±0.06 g/cm3 | Appearance | Solid |

| Color | Off-White to Pale Beige | Solubility | Dioxane (Very Slightly, Heated) |

DBDPE (decabromodiphenyl ether), as a new, highly effective, and environmentally friendly brominated flame retardant, offers numerous significant advantages, specifically in the following areas:

*Highly Efficient Flame Retardancy: DBDPE's extremely high bromine content enables it to rapidly decompose during combustion, producing halogen free radicals. These halogens effectively capture reactive oxygen radicals in the combustion reaction, interrupting the combustion chain and achieving excellent flame retardancy.

*Long-Lasting Stability: DBDPE exhibits excellent thermal stability, maintaining stable flame retardancy even in high-temperature environments, making it suitable for prolonged use.

*Low Persistence: Compared to traditional polybrominated diphenyl ether flame retardants, DBDPE exhibits lower environmental persistence, meaning it does not accumulate in ecosystems over long periods of time, reducing potential harm to wildlife.

*Low Volatility: DBDPE's low volatility reduces potential impacts on the environment and human health during use.

*Low Waste: DBDPE generates less waste during its production process, further reducing environmental impact.

*Multiple Applications: DBDPE is widely used in a variety of applications, including plastics, rubber, resins, coatings, and textiles. As a highly effective additive flame retardant, it can significantly enhance the flame retardancy of these materials.

*Strong Compatibility: DBDPE is highly compatible with other materials without affecting their physical and chemical properties, making it highly versatile in a variety of industrial applications.

*Improved Material Properties: In practical applications, using DBDPE as a flame retardant not only does not compromise the flame retardancy of a material, but can actually improve physical properties such as impact strength, elongation at break, and dimensional stability.

*Enhanced Product Value: By adding DBDPE, manufacturers can produce products that combine excellent flame retardancy with good physical properties, thereby enhancing their market competitiveness.

| Melting point | 345°C |

| Boiling point | 676.2±50.0 °C(Predicted) |

| Density | 2.816±0.06 g/cm3(Predicted) |

| Storage temp. | Sealed in dry,Room Temperature |

| Solubility | Dioxan (Very Slightly, Heated) |

| Form | Solid |

| Color | Off-White to Pale Beige |

Packing: 25kg plastic woven bag, 1*20FCL=20MT with pallet. Also provide 500kg bag and 1,000kg ton bag.

Transport: Non-Hazardous chemicals

Recommended shelf life: 2 years