Email : zhou@sinobiochemistry.com Phone : +86-13941198570

| Availability: | |

|---|---|

| Quantity: | |

DBDPE 99%

Sinobio

29039990

Flame Retardant Decabromodiphenyl Ethane

Decabromodiphenyl ether (DBDPE), CAS No. 84852-53-9, is an important brominated flame retardant. The following is a detailed introduction:

Chinese Name: Decabromodiphenyl ethane

English Name: Decabromodiphenyl ether

Other Names: DBDPE, 1,2-Bis(pentabromophenyl)ethane, Decabrominated diphenyl ethane, etc.

CAS No.: 84852-53-9

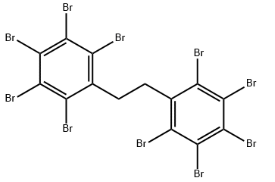

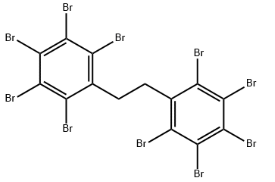

Molecular Formula: C₁₄H₄Br₁₄

Molecular Weight: 971.222

Appearance: White or pale yellow powder

Density: 2.8 ± 0.1 g/cm³ (sometimes 2.816 ± 0.06 g/cm³)

Melting Point: 345°C (sometimes 335-342°C)

Boiling Point: 676.2 ± 50.0 °C (at 760 mmHg)

Flash Point: 346.6 ± 24.8 °C

Solubility: Slightly soluble in alcohol and ether, almost insoluble in water

Decabromodiphenyl ethane (DBDPE), a new functional flame retardant, holds a key position in the flame retardant materials market thanks to its core advantages of broad-spectrum high efficiency and additive-based application properties. Furthermore, its environmentally friendly nature aligns with current trends in green chemistry.

In terms of core performance, DBDPE exhibits multiple outstanding advantages: First, it possesses excellent thermal stability. It is resistant to thermal decomposition during high-temperature processing or long-term use, maintaining its flame retardant effect and effectively preventing performance failure due to thermal degradation. Second, it exhibits excellent UV resistance. When exposed to outdoor UV radiation, its chemical structure and flame retardant properties are not easily damaged by UV rays, significantly improving the outdoor weatherability of applied products. Third, according to information from professional chemical databases such as Chemicalbook, this substance has low toxicity, minimizing potential risks to human health and the ecological environment during production, processing, and use, and ensuring greater safety.

| Chemical Name | Decabromodiphenyl Ethane | CAS No. | 84852-53-9 |

| MF | C14H4Br10 | MW: | 971.22 |

| EINECS | 284-366-9 | Structural Formula |  |

| Melting point | 345 °C | Boiling Point | 676.2±50.0 °C(Predicted) |

| Density | 2.816±0.06 g/cm3 | Appearance | Solid |

| Color | Off-White to Pale Beige | Solubility | Dioxane (Very Slightly, Heated) |

DBDPE, a new, environmentally friendly flame retardant, boasts excellent thermal stability, a very high bromine content, strong UV resistance, and low toxicity. It is widely used in the following areas:

*Plastics Industry: It can be used in plastics such as HIPS (high-impact polystyrene), ABS (acrylonitrile-butadiene-styrene copolymer), PVC (polyvinyl chloride), and PP (polypropylene), improving their flame retardancy.

*Polymers and Engineering Plastics: It also has important applications in styrene-based polymers and engineering thermoplastics.

*Wire and Cable: It is used in the manufacture of wire and cable sheathing and insulation, improving fire safety.

*Other Industries: It can also be used for flame retardant treatment of materials such as elastomers and thermosets.

*Environmental friendliness: Compared to traditional flame retardants like decabromodiphenyl ether, DBDPE lacks ether bonds in its molecular structure, thus preventing the formation of carcinogens such as polybrominated dibenzo-p-dioxins (PBDD) and polybrominated dibenzofurans (PBDF) at high temperatures. Furthermore, it is not subject to the Restriction of the Use of Certain Hazardous Substances in Electrical and Electronic Equipment (RoHS) Directive.

*High Efficiency: DBDPE has an extremely high bromine content and excellent thermal stability, maintaining stable flame retardant properties at high temperatures.

*Broad-spectrum performance: It is suitable for flame retardant treatment of a variety of plastics and polymers, offering a wide range of applications.

25kg plastic woven bag, 1*20FCL=20MT with pallet

Also provide 500kg bag and 1,000kg ton bag

Transport:Non-Hazardous chemicals

Recommended shelf life:2 years

Flame Retardant Decabromodiphenyl Ethane

Decabromodiphenyl ether (DBDPE), CAS No. 84852-53-9, is an important brominated flame retardant. The following is a detailed introduction:

Chinese Name: Decabromodiphenyl ethane

English Name: Decabromodiphenyl ether

Other Names: DBDPE, 1,2-Bis(pentabromophenyl)ethane, Decabrominated diphenyl ethane, etc.

CAS No.: 84852-53-9

Molecular Formula: C₁₄H₄Br₁₄

Molecular Weight: 971.222

Appearance: White or pale yellow powder

Density: 2.8 ± 0.1 g/cm³ (sometimes 2.816 ± 0.06 g/cm³)

Melting Point: 345°C (sometimes 335-342°C)

Boiling Point: 676.2 ± 50.0 °C (at 760 mmHg)

Flash Point: 346.6 ± 24.8 °C

Solubility: Slightly soluble in alcohol and ether, almost insoluble in water

Decabromodiphenyl ethane (DBDPE), a new functional flame retardant, holds a key position in the flame retardant materials market thanks to its core advantages of broad-spectrum high efficiency and additive-based application properties. Furthermore, its environmentally friendly nature aligns with current trends in green chemistry.

In terms of core performance, DBDPE exhibits multiple outstanding advantages: First, it possesses excellent thermal stability. It is resistant to thermal decomposition during high-temperature processing or long-term use, maintaining its flame retardant effect and effectively preventing performance failure due to thermal degradation. Second, it exhibits excellent UV resistance. When exposed to outdoor UV radiation, its chemical structure and flame retardant properties are not easily damaged by UV rays, significantly improving the outdoor weatherability of applied products. Third, according to information from professional chemical databases such as Chemicalbook, this substance has low toxicity, minimizing potential risks to human health and the ecological environment during production, processing, and use, and ensuring greater safety.

| Chemical Name | Decabromodiphenyl Ethane | CAS No. | 84852-53-9 |

| MF | C14H4Br10 | MW: | 971.22 |

| EINECS | 284-366-9 | Structural Formula |  |

| Melting point | 345 °C | Boiling Point | 676.2±50.0 °C(Predicted) |

| Density | 2.816±0.06 g/cm3 | Appearance | Solid |

| Color | Off-White to Pale Beige | Solubility | Dioxane (Very Slightly, Heated) |

DBDPE, a new, environmentally friendly flame retardant, boasts excellent thermal stability, a very high bromine content, strong UV resistance, and low toxicity. It is widely used in the following areas:

*Plastics Industry: It can be used in plastics such as HIPS (high-impact polystyrene), ABS (acrylonitrile-butadiene-styrene copolymer), PVC (polyvinyl chloride), and PP (polypropylene), improving their flame retardancy.

*Polymers and Engineering Plastics: It also has important applications in styrene-based polymers and engineering thermoplastics.

*Wire and Cable: It is used in the manufacture of wire and cable sheathing and insulation, improving fire safety.

*Other Industries: It can also be used for flame retardant treatment of materials such as elastomers and thermosets.

*Environmental friendliness: Compared to traditional flame retardants like decabromodiphenyl ether, DBDPE lacks ether bonds in its molecular structure, thus preventing the formation of carcinogens such as polybrominated dibenzo-p-dioxins (PBDD) and polybrominated dibenzofurans (PBDF) at high temperatures. Furthermore, it is not subject to the Restriction of the Use of Certain Hazardous Substances in Electrical and Electronic Equipment (RoHS) Directive.

*High Efficiency: DBDPE has an extremely high bromine content and excellent thermal stability, maintaining stable flame retardant properties at high temperatures.

*Broad-spectrum performance: It is suitable for flame retardant treatment of a variety of plastics and polymers, offering a wide range of applications.

25kg plastic woven bag, 1*20FCL=20MT with pallet

Also provide 500kg bag and 1,000kg ton bag

Transport:Non-Hazardous chemicals

Recommended shelf life:2 years